Aerogels – amazing new materials

By Kiron Kasbekar | 05 Jan 2024

One day I was trying to get background on one of the topics I cover for my articles and YouTube videos, and I went off at a tangent, as I sometimes do, and began looking at some entirely different subject. It was a subject I had never read or heard about.

It’s a material called aerogel.

-silica-aerogel..jpg)

I thought, ah, a new material! But I quickly discovered that it’s not a new material. Aerogel was first created sometime between 1929 and 1931 by American scientist and chemical engineer Samuel Stephens Kistler.

So what are aerogels?

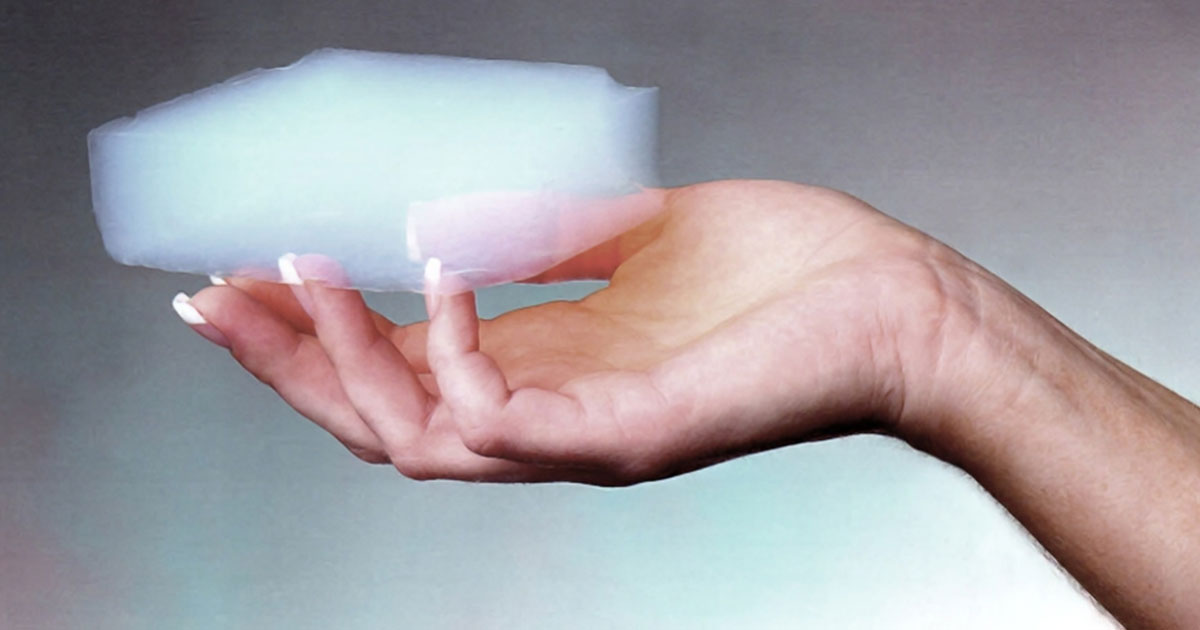

Aerogels are very light and porous materials made from gels, but they feel solid and dry to the touch. They are not like typical gels. You can press on them lightly without leaving a mark, but if you press really hard, they can break like glass, though newer types are more durable.

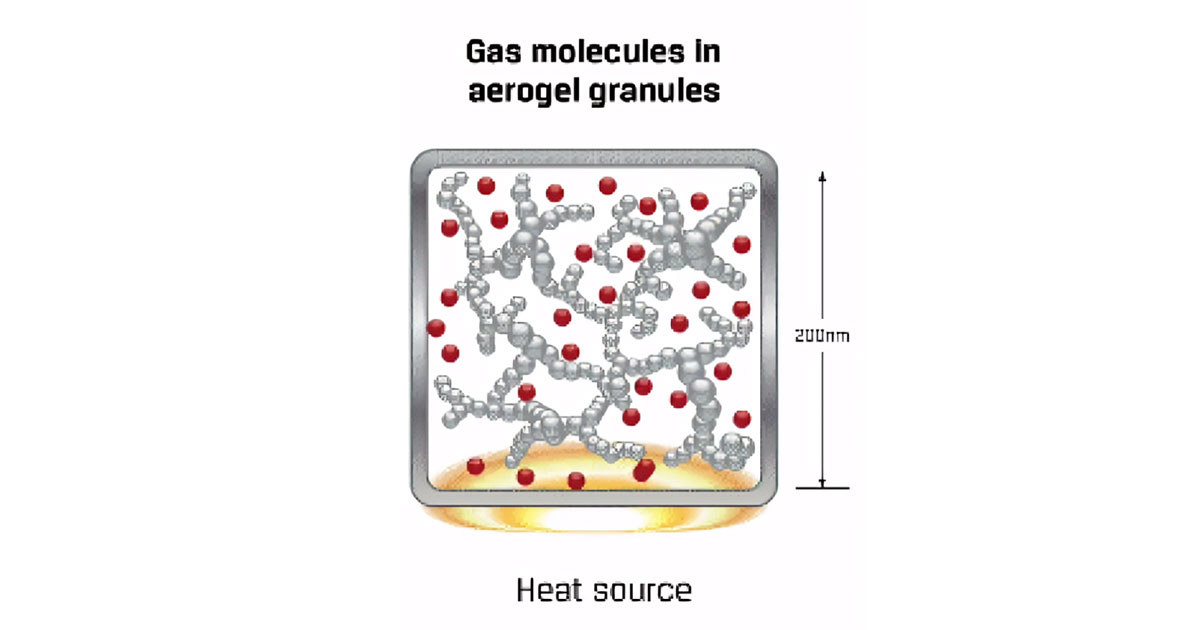

Aerogels are mostly made of air trapped in a solid structure. They are good at stopping heat from moving through them because they don’t conduct heat well. They also don’t allow air to flow inside them, which helps with insulation. However, they are not good at stopping heat transfer through radiation.

To make aerogels, you take the liquid out of a gel in a special way that doesn’t collapse the structure, as would happen with normal drying.

Aerogels can be made from different materials, like silica, polymers, or carbon. Some feel like delicate foam, and others like rigid foam. The first aerogels were made from silica gels, but later on, people used different materials like alumina, chromia, and tin dioxide. They even made carbon aerogels in the late 1980s.

Unique structure

Aerogels are tough because they have a unique structure made up of tiny particles connected together, with big gaps in between. In short, they are mostly air, anywhere from 50% to almost 100%. Most are around 90% to 99.8% air. This makes them great at stopping heat from moving around.

They are good at preventing heat from spreading through them, like a really good blanket, because they are mostly made of air and gases, which don’t let heat pass through easily.

They also stop air from moving around inside them because of their structure. But they’re not great at stopping heat that travels as infrared radiation, like the heat you feel from a warm stove. It can go through aerogels.

One more thing about aerogels is that they can dry things out really well, so they feel dry to the touch. If you handle them for a long time, they can make your skin dry and brittle, so it’s a good idea to wear gloves.

Expensive

While aerogels are some of the lightest known solid materials, they are also among the most expensive.

One square meter of a 1 centimeter thick sheet of aerogel could cost as much as Rs.34,000. So, to install it on a 6 sq. m. window pane, you would have to pay over Rs.2 lakh, plus the cost of an additional pane (for the aerogel has to be sandwiched between two panes) and that of installing it.

That would be the cost, more or less. The benefit would be the savings in electricity because of insulating the house from external heat or cold.

Back to Kistler

Now that I have given a quick introduction to aerogels, let me return to Kistler.

It all started one day when Kistler was trying to make silica gel and accidentally replaced the drying liquid with alcohol. And – surprise, surprise! This seemingly insignificant swap resulted in a gel that didn’t shrink upon drying. Instead, it retained a porous structure, leaving behind a translucent, feather-light material - the first aerogel.

The problem with early aerogels was that they were fragile and susceptible to cracking. Kistler spent years working on improving their stability, exploring different materials and drying techniques.

The 1960s saw significant advancements with the development of silica aerogels by Roy M. Hunt and Robert L. Myerson at Lockheed Martin. These new aerogels were sturdier and opened doors for potential applications.

The space race became a crucial catalyst for aerogel development. NASA recognized its potential for insulating spacecraft and instruments in the harsh environment of space. In the 1960s, the agency contracted Lockheed Martin to develop silica aerogels for the Apollo space program. These lightweight insulators helped regulate temperatures on lunar landers and satellites, proving their worth in extreme conditions.

That was seven decades ago, but they are still not a widely known substance. Do you know why? Because they are very expensive – far more expensive than gold!

In 1992, Hoechst Corp. in Frankfurt, Germany, also began a program for low-cost granular aerogels.

Despite the progress, challenges persisted. High production costs, brittleness in some formulations, and concerns about scalability held back widespread adoption. Nevertheless, persistent research and development efforts are addressing these concerns.

Now let’s look at some of the organizations that are involved with aerogel research and production.

North America

The National Aeronautics and Space Administration (NASA) has been an important user of aerogels. It has used the substance for insulating the pipelines on the ground that fuel the rockets, and also used aerogel pads on spacecraft, both as heat shields during descent to the earth and for insulation from the extreme cold of outer space.

A company called Aspen Systems has been working with NASA since 1992 to produce silica aerogel reinforced with ceramic fibers for the agency’s spacecraft. After beginning with ceramic fibers, Aspen achieved further gains in 1999 by using polyester fibers instead of ceramic fibers to make aerogel for use in spacesuits for the Johnson Space Center.

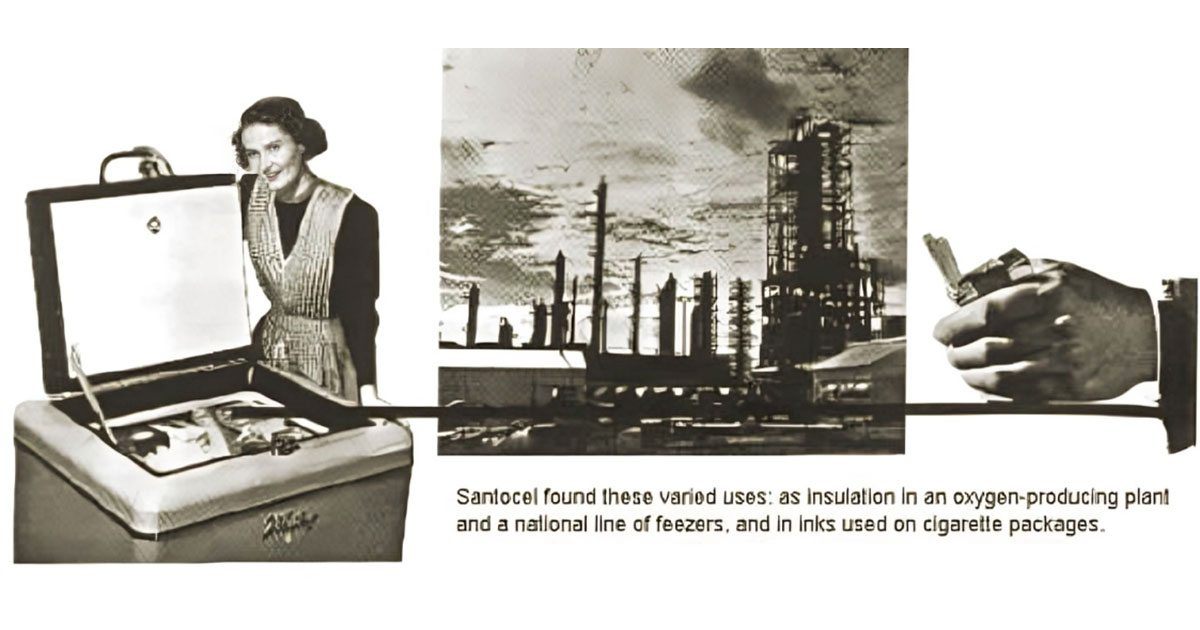

Monsanto was among the first companies to enter the aerogel business. It took up the production of silica aerogels in the 1940s, and began producing a commercially available version called Santocel.

But Monsanto’s involvement with Santocel and aerogels was relatively brief. By the 1960s, the company faced challenges with production costs and competition from other insulating materials, leading it to eventually discontinue production of Santocel around 1970.

Others join the fray

Other organizations carried the baton forward, and now, thanks to their unique properties, aerogels are now used in a variety of areas, including filtration, catalysis, energy storage, and biomedical engineering.

The 1990s ushered in a new era for aerogels. Progress in drying techniques, coupled with growing awareness of their unique properties, fueled renewed interest in aerogels. New materials like carbon nanotubes and graphene were created, leading to the development of even lighter and more efficient aerogels.

Among the leading producers of this material was Cabot Corporation, which in 2001 began making subcritically-dried, waterproof silica aerogel granules under the tradename Nanogel. These granules were first used as insulation in skylights, and are now being used to insulate subsea oil pipelines. Cabot later licensed the technique.

While the development and deployment of aerogels have been prominently associated with American organizations and companies, there have been notable contributions from European and Asian entities over the years. They include:

Europe

.jpg)

- The European Space Agency (ESA): Following the example of NASA, the ESA has used aerogels in space missions since the late 20th century. ESA has incorporated silica aerogels into spacecraft for their thermal insulating properties and ability to capture cosmic dust particles. ESA’s Rosetta mission, launched in 2004, used aerogels to capture dust from the comet 67P/Churyumov-Gerasimenko, providing valuable insights into the composition of cometary material.

- The German Aerospace Center (DLR) has been at the forefront of aerospace research in Europe, and has used aerogels extensively in various space missions. For example, they employed aerogels in the Philae lander during the Rosetta mission to comet 67P/Churyumov-Gerasimenko. The aerogels were used to capture cosmic dust.

- Thales Alenia Space, a joint venture between French technology corporation Thales Group and Italian defense conglomerate Leonardo, has used silica aerogels in space missions, such as the Rosetta mission to protect spacecraft from extreme temperatures in space.

- Researchers at the University of Cambridge in Britain have made significant contributions to aerogel research, particularly in the development of carbon aerogels for energy storage applications, including supercapacitors and batteries.

- Switzerland: Empa (Swiss Federal Laboratories for Materials Science and Technology): Empa has been actively involved in aerogel research and development since the late 20th century. Its researchers have worked on various aspects of aerogels, including silica and polymer-based aerogels. They have contributed to advancements in the synthesis and characterization of aerogels.

- Aerogel Technologies Europe (ATE): ATE is a European subsidiary of the American company, Aerogel Technologies. It has been promoting aerogel-based solutions, including super-insulating materials and coatings, in Europe. Clients include industries such as construction and energy.

Asia

- Researchers at the Tokyo Institute of Technology have been working on the development of highly porous and lightweight aerogels for use in the aerospace and automotive industries. The Japan Aerospace Exploration Agency (JAXA) has collaborated with the National Institute for Materials Science to develop silica aerogels for thermal insulation in the Hayabusa spacecraft, which successfully collected samples from the asteroid Itokawa.

- China has become a major player in aerogel production and application. Shandong University has made important contributions to the synthesis of new aerogel materials and their applications in energy storage devices. And companies like XG Sciences and Shanghai Gefei Fine-Chemical have established themselves as major manufacturers of silica aerogels for construction, electronics, and aerospace applications.

- The Indian Space Research Organisation (ISRO) has used aerogels in its space missions, such as the Chandrayaan-2 mission to the moon to insulate sensitive instruments and protect them from extreme temperatures. Scientists at India’s Defence Research and Development Organization (DRDO) are developing graphene aerogels for supercapacitors and energy storage.

- The National University of Singapore (NUS) is working on cellulose aerogels for water purification and oil spill remediation. Japan continues to innovate with NIRIM focusing on metal oxide aerogels for catalysis and environmental applications.

- The Taiwan Textile Research Institute (TTRI) has explored the use of aerogels in textiles, particularly for the development of lightweight and insulating fabrics with potential applications in outdoor apparel and protective clothing.

- JIOS Aerogel in South Korea is an innovator in critical components for Li-ion battery systems and in the rapidly expanding markets for electric vehicles and energy storage systems.

New applications

Novel production methods like freeze-drying and sol-gel processing are paving the way for more affordable and robust aerogels. Additionally, new applications beyond insulation are emerging, including oil spill cleanup, water purification, and even drug delivery, expanding the horizons of aerogel technology.

Today, the aerogel market is still in its nascent stages, but it’s steadily growing.

.jpg)

Researchers are actively developing next-generation aerogels with enhanced properties like fire resistance, flexibility, and even electrical conductivity. This could unlock their potential in diverse fields like electronics, aerospace, and energy storage. As production costs continue to decrease and more applications are found, aerogels are poised to take off and create solutions for hitherto intractable problems.