Tinplate vs. plastic containers: which is more environmentally friendly? - Part 1

By Aniket Gupta | 14 Aug 2023

As people become increasingly conscious of the environmental impact of our consumption habits, we are pushed to make choices between what we are habituated to doing and what we should be doing. One important issue that has begun troubling us all is: should we be using plastic containers?

Do we have a choice? Of course, we do. There are several, depending on the purpose. One of the alternatives to plastic is tinplate.

The choice between tinplate containers and plastic ones has gained significant attention. Both tinplate and plastic materials serve as practical packaging options for a wide range of products, from food and beverages to personal care items.

However, there are environmental implications of choosing one over the other. In this article, we will look at the environmental issues surrounding tinplate and plastic containers, and explore the advantages and disadvantages of each in terms of their ecological footprint, resource use, recyclability, and overall impact on the planet.

Tinplate

Tinplate, often referred to as tin-coated steel, is a traditional packaging material that offers several advantages from an environmental perspective. When we buy a can of beans or can of fish pickled in brine, we are buying the food packed in tinplate.

Tinplate is a highly durable and long-lasting material. It provides excellent protection for its contents because it is resistant to corrosion, and ensure the integrity of the product throughout its shelf life. This durability reduces the need for frequent replacement and therefore minimizes the demand for raw materials.

On the other hand, plastic containers, made predominantly from petroleum-based polymers, have gained popularity due to their lightweight nature and their versatility. Because of their low weight, plastic-packed stuff reduce transportation emissions, as they require less energy to ship compared to comparatively heavier materials like tinplate.

The problem is that the extraction and processing of petroleum for plastic production contribute to environmental degradation, including habitat destruction, air and water pollution, and greenhouse gas emissions.

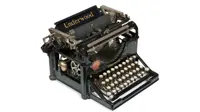

History of tinplate containers

The history of tinplate containers is a fascinating journey that spans centuries and reflects the evolution of packaging and preservation methods.

Tinplate, a thin sheet of iron or steel coated with a layer of tin, has been used for various purposes throughout history, including packaging and storing of a wide range of products.

The use of tinplate-like materials can be traced back to ancient civilizations. Egyptians, Romans, and other cultures used tin-coated iron vessels for storing and transporting liquids, spices, and other goods. The tin coating helped prevent corrosion and maintain the quality of the contents.

The industrial revolution marked a significant turning point in the production of tinplate containers. In the 18th century, advancements in manufacturing processes, including the development of rolling mills and improved tin-coating techniques, made mass production of tinplate containers possible.

Tinplate containers gained further popularity during the 19th century as industrialization and urbanization led to increased demand for convenient and portable packaging. The rise of canning techniques revolutionized food preservation and distribution. Tinplate cans were widely used for preserving perishable goods, making them essential for military rations and long-distance trade.

While tinplate containers continued to dominate packaging, the introduction of other materials, such as aluminum and plastic, posed new challenges and opportunities. Aluminum cans provided a lighter alternative to tinplate, particularly for beverages.

The advent of plastic packaging offered new levels of flexibility, cost-effectiveness and convenience. Plastics gained prominence in packaging preferences in the latter half of the 20th century due to their lightweight nature and versatility.

Plastic containers, bottles, and packaging became ubiquitous in various industries, challenging the dominance of tinplate and other materials.

Read part 2: Tinplate vs. plastic containers: which is more environmentally friendly? - Part 2